Inside Durham University’s New Immersion Cooling Lab

How Vespertec and Midas helped bring immersion cooling to one of the UK’s leading HPC research hubs

Scott Constable, Alliances Director at Vespertec

As we all know, oil and water don’t mix.

Oil and GPUs, though? That one’s worth investigating.

After buying top-end GPUs and server racks, the last thing most people want to do is drop them directly into a vat of oil. But that’s exactly what Durham University did when it plunged 6 AMD- and Intel-powered servers into a 50U tank from Midas Immersion Cooling, marking the next phase of a very exciting project I was lucky enough to experience first-hand.

That project is Durham University’s Immersion Cooling and Heat Storage (ICHS) Living Lab. Given that cooling can account for up to 40% of a data centre’s overall energy usage, Durham’s researchers wanted to investigate the best way to improve Power Utilisation Efficiency (PUE). One of the methods they wanted to test was immersion cooling: an approach that involves dunking compute in dielectric fluid to remove heat more efficiently than air-cooling.

Now, the Midas 50U XCI system, integrated by Vespertec, will help graduates at Durham to run some of the university’s most compute-intensive workloads, from complex simulations to large-scale AI processing, as they put the immersion tank through its paces. If they’re correct, it could become the most effective way to cut data centres’ energy consumption and reuse their waste heat for homes, industrial buildings, and even swimming pools.

The 50U Midas XCI Immersion Cooling Tank Installed in Durham’s DiRAC High Performance Computing Facility (figure 1).

So, how did Durham go from an idea on paper to a live, fully operational immersion system sitting in their lab? What kind of design work, technical back-and-forth, and planning was required to make sure the setup would perform exactly as expected once the servers hit the oil?

Let’s go back to the beginning.

Durham University’s Requirements

When Durham University began planning its new immersion facility, it had a very specific set of requirements. The facility was already a fully operational HPC environment with traditional racks on raised flooring and direct-to-chip cooling in place – but immersion cooling would require something very different.

The immersion tank itself would have to be capable of hosting at least 20U of kit, operate using single-phase immersion cooling based on a mineral oil, have a heat dissipation capacity of at least 1kW/U, and feature remote monitoring and alerting capabilities to keep a close eye on temperature and flow rate. It would also need to be plumbed into the existing primary cooling circuit, with an 18-20°C input and 23-25°C output, and a flow rate of around 100-140 litres per minute.

But no tank is complete without its servers. The planned system would have to hold a minimum of 5 servers, each using dual AMD Bergamo processors (with 256 cores per node), 1.5TB of RAM, and NVIDIA Connect-X6 HDR200 Infiniband connectivity. It would also have to include another node with an Intel CPU, at least 64 cores, 512GB of RAM, and an NVIDIA H100 GPU. All of this needed to come complete with the necessary, immersion-proof cables.

But that wasn’t all. Durham needed a partner who could offer wraparound support: providing on-site support during deployment, hands-on training for their engineers, and a single point of contact for anything that might go wrong. That meant somebody who was ready to collect faulty parts, ship replacements fast, and send an engineer when remote fixes weren’t enough.

How It All Came Together

When Vespertec got involved, our goal was to deliver Durham a solution that could handle the high heat loads generated by its data centre hardware while giving it room to expand over time. We brought together partners we trust and shaped the design into a single, practical system – one that worked straight out of the box and would keep doing so under full load.

After reviewing the requirements with the university team, we proposed the 50U MIDAS XCI™ TANK – a fully redundant, single-phase system capable of dissipating up to 150 kW of heat depending on the cooling loop. The tank works with a wide variety of dielectric fluids, and for this project we selected Valvoline dielectric mineral oil. It also features full fault tolerance, concurrent maintainability, and SNMP-based monitoring. Most importantly, it runs independently, so Durham can operate it as a self-contained lab or expand to multiple tanks later.

Each Cooling Distribution Unit (CDU) includes 1N, 2N, or 2N + 1 redundancy options, automatically failing over in the event of a fault to maintain uptime. The CDUs are hot-swappable and can be replaced in under 10 minutes without tools, with workloads remaining live during maintenance, so there’s no need to shut down the system during servicing or when you’re replacing a component.

The system connects directly to Durham’s existing chilled-water loop using 2-inch dry disconnects. At a tank temperature of 50°C (the hottest point in the cycle) the setup can dissipate around 120 kW with an incoming water temperature of 30°C at 140 litres per minute.

Inside, MIDAS’s patented system uses forced convection to make sure fluid is circulating through the tank (injected from the base, recovered at the top), and maintains a stable thermal envelope even under full load. Its proprietary controller, network port, and graphical user interface communicate remotely through SNMP to capture inlet/outlet temperatures, pressure, and flow on both oil and water circuits and feed automatic alerts into Durham’s management platform.

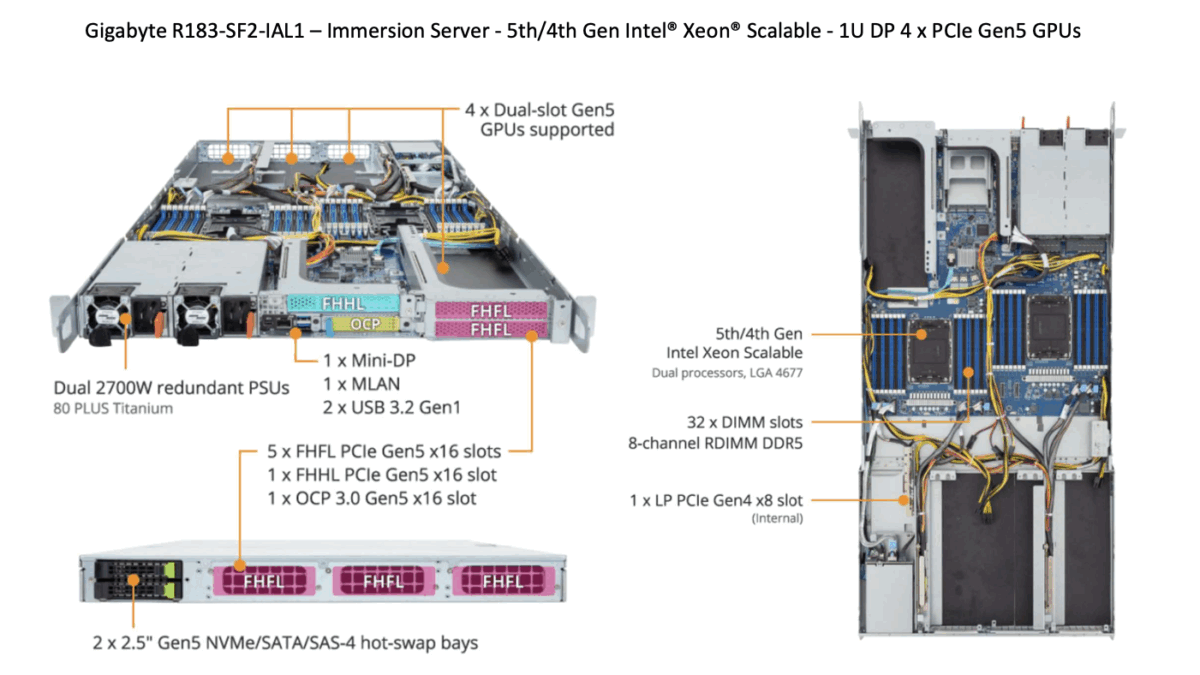

We paired the tank with five Gigabyte R183-ZF2-IAL1 servers running dual AMD EPYC 9754 128-core processors, each with 1.5 TB DDR5, plus a Gigabyte R183-SF2-IAL1 node powered by dual Intel Xeon Gold 6530 CPUs and an NVIDIA H100 GPU. All systems use immersion-ready cabling, ConnectX-6 HDR200 InfiniBand, and the university’s existing APC AP8886 PDU with 32 A three-phase power.

Vespertec’s solution design for the Gigabyte Immersion Server nodes (figure 2).

Finally, before loading them onto our vehicles for delivery to Durham, we fully assembled and stress-tested every node at our Stockport configuration centre, making sure we could personally verify the reliability and performance of the hardware. We applied the same testing process we use for immersion-ready systems in our own lab, making sure Durham’s hardware arrived ready to go.

Then came the big day.

Installation Day – the fun bits

When we arrived on campus with the lorry and crane, I’ll admit I was slightly nervous. We’d planned everything down to the last detail, but what if something unexpected went wrong? Would everything still work?

Turns out, there was no reason to worry!

The 50U Midas XCI Immersion Cooling Tank Installed in Durham’s DiRAC High Performance Computing Facility (figure 3).

Vespertec, Midas, and Durham engineers worked side by side to get the tank through some very tight access routes. The team used a dedicated tail-lift vehicle to bring it from Stockport, then shifted the 600-litre unit into position using pump trucks and floor skates. Once in place, we handled the full integration: connecting the tank to the university’s chilled-water loop via 2-inch dry disconnects, setting the flow rate to 120 L/min, and verifying temperature differentials across the circuit.

Next came the fill: 440 gallons of Valvoline dielectric fluid, circulated until every air pocket was cleared and flow sensors stabilised. With that done, each server was immersed and powered up one by one while the CDU controllers balanced the pressure and confirmed the coolant was flowing as expected.

Durham’s HPC engineers joined the installation directly, working alongside Vespertec and Midas engineers through setup and commissioning. The session covered how to operate the tank day to day, monitor key metrics, and handle basic maintenance tasks such as draining, refilling, and CDU checks before the formal handover.

But our job doesn’t end once the tank’s in place. We provide full wraparound support, which covers everything from parts replacement and on-site engineering to ongoing checks with Midas and Valvoline. Durham’s team know they can call us any time something needs attention, whether that’s a quick fix, a fluid sample shipment, or something bigger.

The hardest part was physically lifting 50U of kit into a facility with a raised dock. We’d planned it down to the millimetre, and it went much more smoothly than anyone expected. The Durham team were patient and steady throughout, which made the whole job painless, and once the packaging was cleared and the courier drove off, the tank looked like it had always been there. Before long, Durham had its own immersion system up and running – looking like it had been there the whole time!

What’s next?

Together with Midas, we’ll be running periodic analysis on the Valvoline dielectric fluid to monitor its condition over time. Every few months, we’ll take a fresh vial and share it back with their lab for comparison – checking for any trace of degradation or shift in chemical composition as the system runs under load.

That’s exactly the kind of long-term data that researchers need to understand how immersion behaves in a real HPC environment. Six months from now, we’ll have a full record of fluid stability, efficiency, and performance – and so far, everything’s looking solid. Stay tuned for the results.

If this blog struck your fancy, and you’re curious to know how you could plan, prepare, and install your very own immersion solution, get in touch with us today.

Our Vespertec + MIDAS immersion cooling solution is a proven, scalable platform. You can start with a single tank to validate performance and reliability, then expand to multiple tanks populated with high-density HPC and AI servers on the same manifold architecture, enabled by a modular, plug & play design and MIDAS’ patented redundant system that delivers 99.99% uptime, even during maintenance.

With over 4,000 tanks installed worldwide, nearly 500 MW cooled to date, and documented PUE below 1.05, it’s a field-tested solution with continuous R&D that scales in step with your innovation, efficiency, and sustainability goals.